Maintaining precise refrigerator temperature control is essential for food safety, energy efficiency, and extending the lifespan of perishable goods. Whether you operate a commercial kitchen, laboratory, or simply want to optimize your home refrigeration system, understanding the fundamentals of temperature management can save you money while ensuring optimal preservation conditions. Modern refrigeration systems rely on sophisticated control mechanisms that regulate cooling cycles, monitor ambient conditions, and maintain consistent internal temperatures across different storage zones.

Understanding Temperature Control Fundamentals

The Science Behind Refrigeration Temperature Management

Effective refrigerator temperature control operates on the principle of heat transfer and thermodynamic equilibrium. When you set a target temperature, the control system continuously monitors the internal environment using precision sensors that detect even minor fluctuations. These sensors communicate with the compressor, evaporator fans, and defrost cycles to maintain stable conditions. The control algorithm calculates the optimal timing for cooling cycles based on factors such as ambient temperature, door openings, and thermal load within the storage compartment.

Digital temperature controllers have revolutionized how we manage refrigeration systems by providing real-time monitoring capabilities and programmable settings. Unlike traditional mechanical thermostats that rely on bimetallic strips or gas-filled bulbs, modern digital controllers use electronic sensors and microprocessor-based logic to achieve superior accuracy. This technological advancement allows for temperature stability within ±0.1°C in many professional applications, ensuring that sensitive products remain within their required storage parameters.

Key Components of Modern Control Systems

Contemporary refrigerator temperature control systems consist of several interconnected components that work together to maintain optimal conditions. The primary sensor, typically a thermistor or RTD probe, measures the actual temperature and transmits this data to the control unit. The controller then compares this reading against the setpoint and determines whether cooling is needed. Advanced systems may include multiple sensors for different zones, humidity monitoring, and even predictive algorithms that anticipate temperature changes based on usage patterns.

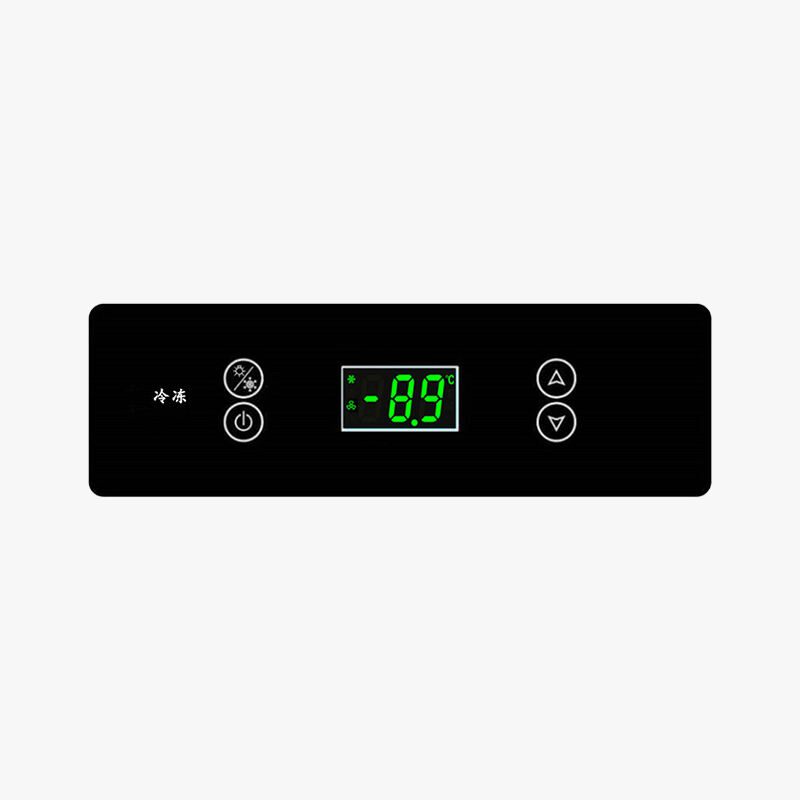

The control interface allows operators to adjust settings, view current readings, and configure alarm parameters for temperature deviations. Many modern controllers feature digital displays that show both current and target temperatures, along with status indicators for various system functions. Some units also provide data logging capabilities, recording temperature trends over time for compliance documentation and system optimization purposes.

Optimal Temperature Settings for Different Applications

Commercial Food Service Requirements

Commercial refrigeration applications demand precise refrigerator temperature control to comply with food safety regulations and maintain product quality. Most fresh foods require storage temperatures between 32°F and 40°F (0°C to 4°C), while frozen products must be maintained at 0°F (-18°C) or below. These ranges are not arbitrary but based on scientific research that identifies the temperature thresholds where bacterial growth slows significantly and food quality degradation is minimized.

Different food categories have specific temperature requirements within these general ranges. Dairy products perform best at 35°F to 38°F (2°C to 3°C), while fresh produce may require slightly different conditions depending on the type. Leafy greens benefit from temperatures around 32°F (0°C) with high humidity, whereas fruits like apples and pears maintain quality longer at 30°F to 32°F (-1°C to 0°C). Understanding these nuances allows foodservice operators to optimize their refrigerator temperature control strategies for different storage areas.

Laboratory and Medical Storage Standards

Laboratory and medical applications often require more stringent refrigerator temperature control than commercial food storage. Pharmaceutical products, vaccines, and biological samples frequently have narrow temperature ranges that must be maintained continuously. Many vaccines, for example, must be stored between 35°F and 46°F (2°C to 8°C), with some requiring even tighter tolerances. Temperature excursions outside these ranges can compromise product efficacy and render expensive medications unusable.

Medical-grade refrigeration systems incorporate additional safety features such as redundant sensors, backup power systems, and continuous monitoring with alarm capabilities. These systems often require temperature mapping studies to verify uniform conditions throughout the storage space and may need calibration certificates to demonstrate compliance with regulatory requirements. The investment in precise refrigerator temperature control equipment is justified by the high value of stored products and the critical nature of temperature stability.

Installation and Calibration Best Practices

Proper Sensor Placement Techniques

Achieving accurate refrigerator temperature control begins with proper sensor placement within the storage compartment. The location of temperature sensors significantly impacts the effectiveness of the control system, as refrigerators often have temperature variations between different areas. The ideal sensor location is typically in the geometric center of the storage space, away from direct airflow from evaporator coils and insulated from the effects of door openings and product loading.

In larger commercial units, multiple sensors may be necessary to monitor temperature uniformity across the entire storage volume. These sensors should be positioned at different heights and depths within the compartment to provide a comprehensive picture of thermal conditions. The sensor probe should be secured properly to prevent movement during normal operations while ensuring good thermal contact with the air or medium being monitored. Some applications benefit from immersing sensors in thermal mass simulators that better represent the temperature of stored products.

Calibration and Maintenance Procedures

Regular calibration ensures that refrigerator temperature control systems maintain their accuracy over time. Environmental factors, electrical interference, and normal component aging can cause sensor drift that gradually affects temperature readings. Professional calibration typically involves comparing the system sensors against certified reference standards at multiple temperature points across the operating range. This process should be documented with calibration certificates that include traceability to national standards.

Maintenance procedures for temperature control systems include cleaning sensor probes, checking electrical connections, and verifying control parameters. Dust accumulation on sensors can insulate them from air temperature changes, while corroded connections can introduce electrical resistance that affects readings. The controller software should be reviewed periodically to ensure that setpoints, alarm limits, and control parameters remain appropriate for the application. Some systems benefit from firmware updates that improve performance or add new features.

Troubleshooting Common Temperature Control Issues

Identifying Temperature Fluctuation Patterns

Temperature instability in refrigeration systems often follows recognizable patterns that can help diagnose underlying problems. Short-cycle fluctuations where temperatures rise and fall rapidly typically indicate issues with the refrigerator temperature control settings or sensor placement. The controller may be responding too aggressively to minor temperature changes, causing the cooling system to cycle on and off frequently. This not only wastes energy but can also create temperature swings that affect product quality.

Longer-term temperature drifts may indicate problems with the refrigeration system itself, such as low refrigerant levels, dirty condenser coils, or failing compressor components. These issues cause the system to lose cooling capacity gradually, forcing the refrigerator temperature control system to call for cooling more frequently without achieving the desired results. Monitoring temperature trends over time helps distinguish between control system problems and mechanical refrigeration issues.

Addressing Sensor and Control Malfunctions

Faulty sensors are among the most common causes of refrigerator temperature control problems. Symptoms include erratic temperature readings, failure to respond to temperature changes, or readings that remain constant despite obvious temperature variations. Testing sensors typically involves comparing their output against known reference temperatures or using calibrated test equipment. Digital controllers often provide diagnostic information that can help identify sensor problems, including open circuits, short circuits, or out-of-range readings.

Control system malfunctions may manifest as failure to activate cooling, incorrect response to temperature changes, or inability to maintain setpoint temperatures. These problems often require systematic troubleshooting that examines power supply voltage, control signal integrity, and output relay operation. Modern digital controllers include self-diagnostic features that monitor internal functions and provide error codes when problems are detected. Understanding these diagnostic capabilities helps technicians identify and resolve refrigerator temperature control issues more efficiently.

Advanced Features and Smart Technology Integration

Remote Monitoring and Alert Systems

Modern refrigerator temperature control systems increasingly incorporate connectivity features that enable remote monitoring and automated alert systems. These capabilities allow facility managers to monitor multiple refrigeration units from a central location and receive immediate notifications when temperature excursions occur. Wireless communication protocols such as WiFi, cellular, or dedicated radio networks connect individual controllers to cloud-based monitoring platforms that provide real-time status information and historical data analysis.

Alert systems can be configured to notify personnel through multiple channels including email, SMS text messages, and phone calls when temperature problems are detected. This immediate notification capability is particularly valuable for applications where product loss due to temperature excursions would be costly or dangerous. Some systems provide escalating alert sequences that contact additional personnel if initial alerts are not acknowledged within specified time periods, ensuring that critical temperature problems receive prompt attention.

Data Logging and Compliance Documentation

Comprehensive data logging capabilities have become essential features of professional refrigerator temperature control systems, particularly in regulated industries such as pharmaceuticals, food service, and healthcare. These systems continuously record temperature readings at programmed intervals, creating detailed historical records that demonstrate compliance with storage requirements. Data logging memory can typically store months or years of temperature data, depending on the sampling frequency and storage capacity of the controller.

The recorded data can be exported in various formats for analysis, reporting, and regulatory compliance documentation. Many systems generate automated reports that summarize temperature performance over specified periods, highlighting any excursions outside acceptable ranges and providing statistical analysis of temperature stability. This documentation capability supports quality management systems and helps organizations demonstrate compliance with industry standards and regulatory requirements for temperature-sensitive storage applications.

Energy Efficiency and Cost Optimization

Strategic Temperature Management for Energy Savings

Optimizing refrigerator temperature control settings can significantly reduce energy consumption while maintaining product safety and quality. Setting temperatures only as low as necessary for the specific application prevents the cooling system from working harder than required. Even small increases in setpoint temperature can yield substantial energy savings, as refrigeration energy consumption increases exponentially as temperatures approach the freezing point of water.

Advanced control strategies such as adaptive defrost cycles and variable-speed compressor operation further improve energy efficiency. These systems monitor actual conditions rather than relying on fixed timer schedules, activating defrost cycles only when needed and adjusting compressor speed based on cooling demand. Smart refrigerator temperature control systems can learn usage patterns and adjust operation schedules accordingly, reducing energy consumption during periods of low thermal load while ensuring adequate cooling capacity during peak demand periods.

Lifecycle Cost Considerations

Investing in high-quality refrigerator temperature control equipment often provides long-term cost benefits that extend beyond initial purchase price considerations. Precise temperature control reduces product spoilage and waste, which can represent significant cost savings over time. In commercial food service applications, preventing temperature-related food loss often justifies the cost of upgraded control systems within months of installation.

Reliable temperature control also extends the operational life of refrigeration equipment by preventing excessive cycling and reducing stress on compressor and other mechanical components. Systems that maintain stable temperatures require less frequent maintenance and experience fewer component failures, reducing both direct repair costs and indirect costs associated with system downtime. When evaluating refrigerator temperature control options, decision-makers should consider the total cost of ownership including energy consumption, maintenance requirements, and product protection benefits.

FAQ

What is the ideal temperature range for refrigerator temperature control systems

The ideal temperature range depends on the application, but most commercial refrigerators should maintain temperatures between 35°F and 40°F (2°C to 4°C) for general food storage. Medical and laboratory applications may require different ranges, with many pharmaceuticals needing storage between 36°F and 46°F (2°C to 8°C). Frozen storage applications typically require temperatures at or below 0°F (-18°C). The key is maintaining consistent temperatures within the specified range rather than allowing significant fluctuations that can compromise product quality and safety.

How often should refrigerator temperature control systems be calibrated

Professional refrigerator temperature control systems should undergo calibration at least annually, though some regulated applications may require more frequent calibration every six months or quarterly. The calibration frequency depends on the criticality of the application, regulatory requirements, and the stability characteristics of the specific control equipment. Systems used for pharmaceutical storage or research applications typically need more frequent calibration than general food service equipment. Signs that immediate calibration may be needed include unusual temperature readings, difficulty maintaining setpoints, or significant changes in system performance.

What causes temperature fluctuations in refrigerator control systems

Temperature fluctuations can result from various factors including improper sensor placement, incorrect control parameters, mechanical problems with the refrigeration system, or excessive thermal load from frequent door openings. Poor insulation, dirty condenser coils, or low refrigerant levels can also cause temperature instability. In some cases, the refrigerator temperature control system may be oversensitive, causing the cooling system to cycle too frequently. Identifying the root cause requires systematic analysis of temperature patterns, system operation cycles, and environmental factors affecting the refrigeration unit.

Can smart technology improve refrigerator temperature control performance

Smart technology integration significantly enhances refrigerator temperature control performance through features like remote monitoring, predictive maintenance alerts, and automated reporting capabilities. These systems can detect problems before they cause product loss, optimize energy consumption based on usage patterns, and provide detailed documentation for compliance requirements. Cloud-based monitoring platforms enable centralized management of multiple refrigeration units and can alert personnel immediately when temperature problems occur. Advanced algorithms can also learn from operational data to optimize control parameters automatically, improving both temperature stability and energy efficiency over time.