Setting up a temperature controller properly is crucial for maintaining optimal environmental conditions in industrial applications, laboratory settings, and commercial facilities. A well-configured temperature controller ensures precise temperature regulation, energy efficiency, and equipment longevity. Understanding the fundamental principles and setup procedures helps operators achieve consistent performance while minimizing operational costs and preventing costly temperature-related failures.

Understanding Temperature Controller Components and Functions

Essential Hardware Components

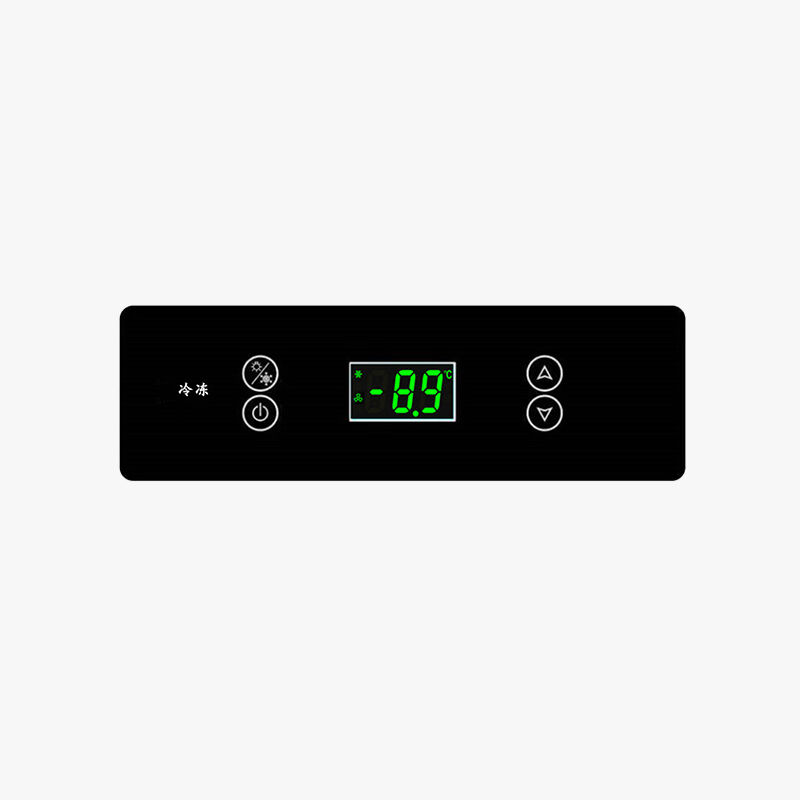

Modern temperature controller systems consist of several interconnected components that work together to maintain precise temperature control. The main unit features a digital display, input terminals for temperature sensors, output relays for heating and cooling devices, and programming buttons for configuration. Temperature sensors, typically thermocouples or RTDs, provide real-time temperature feedback to the controller, enabling accurate monitoring and adjustment of environmental conditions.

Power supply requirements vary depending on the specific temperature controller model, with most industrial units operating on standard AC voltage or low-voltage DC power. Output contacts handle the switching of heating elements, cooling compressors, fans, and alarm systems based on programmed temperature parameters. Understanding these components helps technicians identify potential issues during installation and troubleshoot problems effectively when they arise during operation.

Control Algorithm Principles

Temperature controller algorithms utilize PID control logic to maintain stable temperature conditions with minimal overshoot and oscillation. Proportional control adjusts output power based on the difference between setpoint and actual temperature, while integral control eliminates steady-state errors over time. Derivative control responds to the rate of temperature change, preventing excessive overshoot and improving system stability during rapid temperature transitions.

Advanced temperature controller models incorporate adaptive tuning features that automatically optimize PID parameters based on system characteristics and load conditions. These intelligent algorithms learn from system behavior and adjust control parameters to achieve optimal performance without manual intervention. Understanding control principles enables operators to fine-tune settings for specific applications and achieve superior temperature stability in demanding environments.

Pre-Installation Planning and Safety Considerations

Site Assessment and Requirements

Proper site assessment ensures successful temperature controller installation and long-term reliability. Environmental factors such as ambient temperature, humidity levels, vibration, and electromagnetic interference affect controller performance and longevity. Installation locations should provide adequate ventilation, protection from moisture, and easy access for maintenance and programming activities while maintaining safe distances from heat sources and electrical interference.

Power requirements must be verified against available electrical infrastructure, including voltage ratings, current capacity, and grounding systems. Load calculations help determine the appropriate temperature controller size and output capacity needed to handle connected heating and cooling equipment. Documentation of existing wiring, control panels, and safety systems facilitates integration planning and reduces installation time while ensuring compliance with electrical codes and safety standards.

Safety Protocols and Electrical Considerations

Electrical safety protocols must be followed throughout the temperature controller installation process to prevent accidents and equipment damage. Power isolation procedures require proper lockout tagout practices, verification of zero energy states, and use of appropriate personal protective equipment. Grounding systems must comply with local electrical codes and provide adequate protection against electrical faults and lightning strikes that could damage sensitive electronic components.

Temperature controller wiring must meet industry standards for insulation ratings, conductor sizing, and environmental protection. Segregation of power and signal cables prevents electromagnetic interference that could cause erratic controller operation or false temperature readings. Installation of surge protection devices and proper cable routing techniques protect the temperature controller from electrical disturbances and extend equipment service life significantly.

Step-by-Step Installation Process

Physical Mounting and Panel Integration

Begin the temperature controller installation by selecting an appropriate mounting location within the control panel that provides adequate clearance for ventilation and cable connections. Use the manufacturer-supplied mounting hardware to secure the unit firmly to the panel, ensuring proper alignment and gasket sealing for environmental protection. Verify that the mounting orientation allows for easy viewing of the display and access to programming buttons during normal operation and maintenance activities.

Panel cutouts must match the temperature controller dimensions precisely to ensure proper fit and environmental sealing. Remove any sharp edges or burrs from the cutout that could damage cables or create safety hazards during installation. Install any required mounting brackets, strain reliefs, and cable glands according to manufacturer specifications to maintain proper ingress protection ratings and prevent cable damage from vibration or movement.

Electrical Connections and Wiring

Connect power supply wiring first, ensuring proper voltage matching and polarity for DC-powered temperature controller units. Use appropriate wire gauges based on current ratings and installation distances to minimize voltage drop and ensure reliable operation. Install fuses or circuit breakers as specified in the manufacturer documentation to provide overcurrent protection for the controller and connected equipment.

Temperature sensor connections require careful attention to wire routing and shielding to prevent interference and ensure accurate temperature measurement. Thermocouple wiring must maintain proper polarity and use extension cables with matching temperature coefficients to avoid measurement errors. RTD sensors require careful attention to lead resistance compensation and proper connection configuration to achieve specified accuracy levels throughout the operating range.

Programming and Configuration Procedures

Initial Setup Parameters

Access the temperature controller programming menu using the manufacturer-specified button sequence or software interface. Configure basic parameters including temperature units, sensor type, input range, and display resolution according to application requirements. Set appropriate alarm thresholds, output assignments, and communication parameters to integrate the controller with existing monitoring and control systems effectively.

Calibration procedures ensure accurate temperature measurement and control performance throughout the operating range. Follow manufacturer guidelines for offset adjustments, span corrections, and multi-point calibration using certified reference standards. Document all calibration values and configuration settings for future reference and regulatory compliance requirements in critical applications where temperature accuracy is essential for product quality or safety.

Advanced Control Settings

PID parameter tuning optimizes temperature controller performance for specific applications and load characteristics. Start with manufacturer-recommended default values and adjust proportional gain to achieve stable control without excessive oscillation. Integral time constants eliminate steady-state errors while derivative settings improve response to load disturbances and setpoint changes in dynamic applications.

Advanced features such as cascade control, adaptive tuning, and multi-zone coordination require careful configuration to achieve desired performance levels. Set appropriate deadbands, output limits, and rate limiting parameters to prevent equipment damage and ensure smooth operation during startup and load changes. Test all alarm functions and safety interlocks to verify proper operation before placing the temperature controller system into service.

Testing and Commissioning Procedures

Functional Verification Testing

Systematic testing procedures verify that the temperature controller operates correctly under all expected conditions and load scenarios. Begin with basic functionality tests including display operation, button responses, and alarm acknowledgment to confirm proper installation and configuration. Verify temperature sensor readings against calibrated reference instruments to ensure measurement accuracy within specified tolerances.

Output testing confirms that heating and cooling equipment responds appropriately to temperature controller commands. Monitor relay contact operation, analog output signals, and communication interfaces to verify proper system integration. Test emergency shutdown functions and safety interlocks to ensure that the temperature controller provides adequate protection against equipment damage and personnel hazards during abnormal operating conditions.

Performance Optimization

Performance testing evaluates temperature controller stability, response time, and accuracy under normal operating conditions. Monitor setpoint tracking, overshoot characteristics, and settling time to identify opportunities for PID parameter optimization. Record temperature profiles during startup, steady-state operation, and load changes to establish baseline performance metrics for future troubleshooting and maintenance activities.

Energy efficiency optimization involves adjusting control parameters to minimize heating and cooling energy consumption while maintaining required temperature stability. Fine-tune deadband settings, output cycling rates, and anticipatory control features to reduce energy costs without compromising temperature control performance. Document optimized settings and performance metrics to facilitate future system upgrades and maintenance planning activities.

Maintenance and Troubleshooting Guidelines

Preventive Maintenance Procedures

Regular maintenance ensures reliable temperature controller operation and extends equipment service life significantly. Schedule periodic calibration checks using certified reference standards to verify measurement accuracy and identify drift trends before they affect process control. Clean dust and debris from ventilation openings and internal components to maintain proper cooling and prevent overheating failures in harsh industrial environments.

Inspect electrical connections for signs of corrosion, loosening, or overheating that could cause intermittent operation or complete failure. Check cable insulation for damage, wear, or environmental degradation that might allow moisture intrusion or signal interference. Replace backup batteries in temperature controller units with memory retention features according to manufacturer recommendations to prevent configuration loss during power outages.

Common Issues and Solutions

Temperature measurement errors often result from sensor problems, wiring issues, or calibration drift rather than temperature controller failures. Verify sensor resistance values, continuity, and insulation integrity using appropriate test equipment. Check for loose connections, damaged cables, or electromagnetic interference sources that could affect measurement accuracy and control stability in sensitive applications.

Control instability problems typically involve incorrect PID parameters, mechanical issues with heating and cooling equipment, or external disturbances affecting the controlled process. Analyze temperature trends and controller output patterns to identify the root cause of oscillation or poor setpoint tracking. Adjust control parameters systematically and document changes to achieve optimal performance while maintaining system stability under varying load conditions.

FAQ

What type of temperature sensor works best with digital temperature controllers?

The choice between thermocouples and RTDs depends on your specific application requirements. Thermocouples offer wide temperature ranges and fast response times, making them ideal for high-temperature industrial processes. RTDs provide superior accuracy and stability for precision applications but have more limited temperature ranges. Consider factors such as accuracy requirements, response time, environmental conditions, and budget when selecting sensors for your temperature controller system.

How often should I calibrate my temperature controller system?

Calibration frequency depends on application criticality, environmental conditions, and regulatory requirements. Critical processes may require monthly or quarterly calibration, while general HVAC applications might only need annual verification. High-temperature environments, corrosive atmospheres, and applications with frequent thermal cycling typically require more frequent calibration to maintain accuracy. Establish a calibration schedule based on your specific conditions and document all results for regulatory compliance.

Can I install multiple temperature controllers on the same electrical panel?

Yes, multiple temperature controllers can be installed in the same panel with proper planning and electrical isolation. Ensure adequate spacing for ventilation and heat dissipation between units. Provide separate power supplies or adequate current capacity for all controllers and connected equipment. Consider electromagnetic interference between units and implement proper cable routing and shielding techniques to prevent interference between temperature measurement circuits and control outputs.

What should I do if my temperature controller displays error messages?

Error messages typically indicate sensor failures, wiring problems, or configuration issues rather than controller malfunctions. Consult the manufacturer manual to interpret specific error codes and recommended troubleshooting steps. Common solutions include checking sensor connections, verifying power supply voltage, and reviewing configuration parameters. Document error patterns and conditions to help identify recurring problems and implement permanent solutions rather than temporary fixes.