Maintaining optimal refrigerator temperature control is essential for food safety, energy efficiency, and preserving the quality of your stored items. Whether you're managing a commercial kitchen, laboratory facility, or household refrigeration system, understanding the fundamentals of temperature regulation can significantly impact both operational costs and food preservation outcomes. Modern refrigeration systems rely on sophisticated refrigerator temperature control mechanisms that monitor and adjust cooling cycles to maintain consistent internal temperatures across different zones and compartments.

Professional refrigeration applications demand precise temperature management to comply with health regulations and maintain product integrity. Commercial establishments, research facilities, and industrial operations require advanced refrigerator temperature control systems that can handle varying load conditions while maintaining strict temperature parameters. These systems must respond quickly to door openings, ambient temperature changes, and fluctuating product loads to ensure consistent performance throughout the day.

Understanding Refrigeration Temperature Zones

Fresh Food Storage Requirements

Fresh food compartments typically require temperatures between 35°F and 38°F (1.7°C to 3.3°C) for optimal preservation. This temperature range slows bacterial growth while preventing freezing damage to delicate produce and dairy products. Effective refrigerator temperature control systems maintain these conditions by continuously monitoring internal temperatures and adjusting compressor cycles accordingly. The precision of temperature regulation directly affects food safety compliance and waste reduction in both commercial and residential applications.

Different food categories within the fresh storage zone may benefit from slight temperature variations. Leafy greens perform best at temperatures closer to 32°F (0°C), while tropical fruits require slightly warmer conditions around 40°F (4.4°C). Advanced refrigerator temperature control systems can accommodate these variations through zone-specific temperature management, allowing operators to optimize storage conditions for different product types simultaneously.

Freezer Compartment Standards

Freezer sections require consistent temperatures at or below 0°F (-18°C) to maintain food quality and safety standards. Professional-grade refrigerator temperature control systems ensure rapid temperature recovery after door openings and maintain uniform temperatures throughout the freezer compartment. This level of control prevents ice crystal formation that can damage cellular structure in frozen foods and compromise texture and nutritional value over extended storage periods.

Commercial freezer applications often require even stricter temperature control, with some specialty applications demanding temperatures as low as -10°F (-23°C) or lower. These extreme conditions require sophisticated refrigerator temperature control mechanisms that can handle the increased energy demands while maintaining precise temperature regulation. The ability to maintain these low temperatures consistently is crucial for long-term storage applications and specialty food preservation requirements.

Digital Temperature Control Technologies

Microprocessor-Based Systems

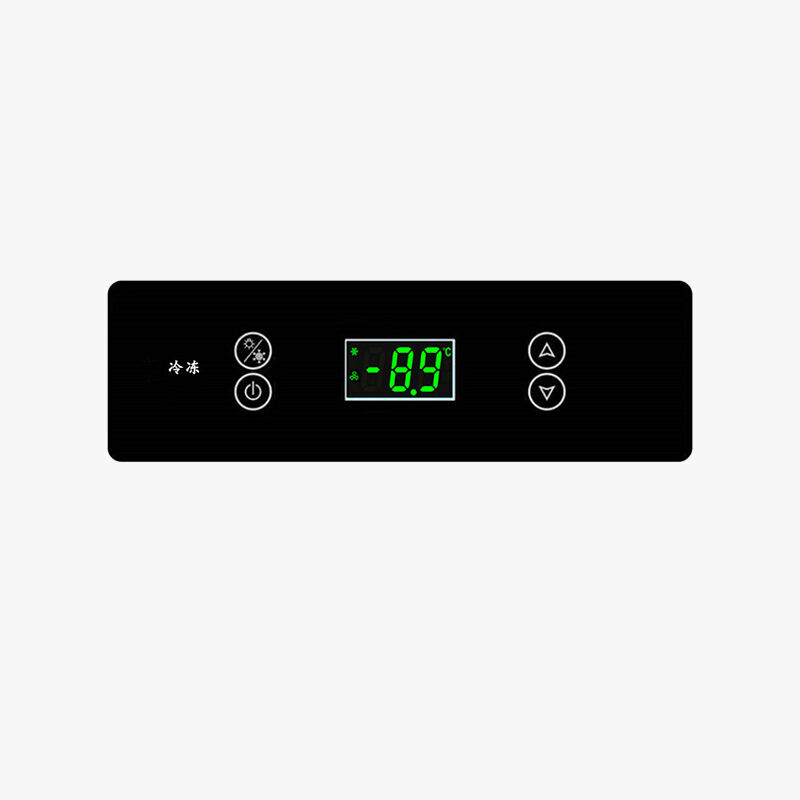

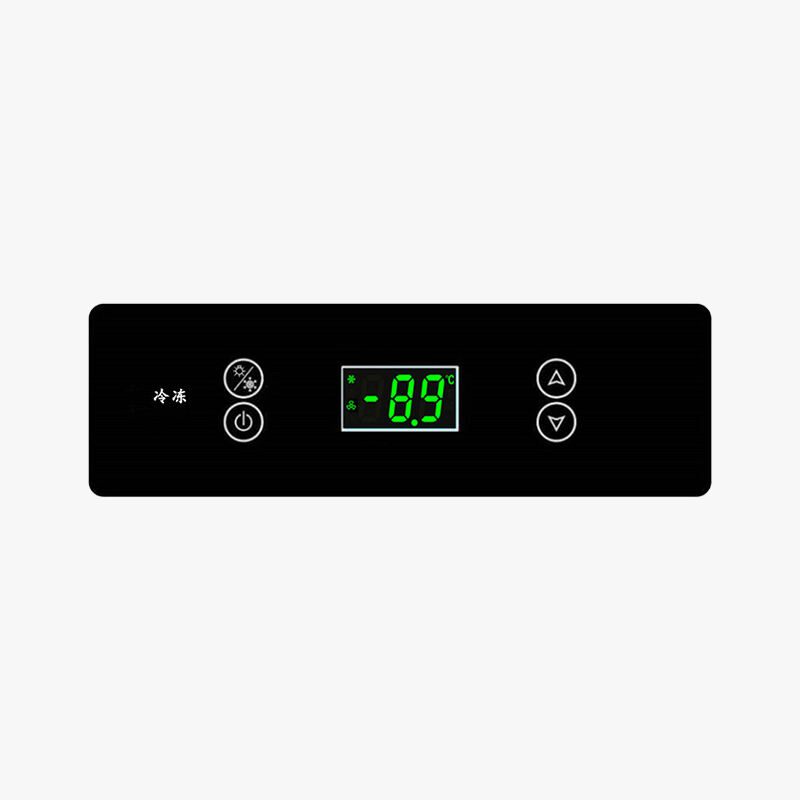

Modern refrigerator temperature control systems utilize advanced microprocessor technology to provide precise temperature regulation and monitoring capabilities. These digital controllers can maintain temperature accuracy within ±1°F (±0.5°C) while continuously logging temperature data for compliance and optimization purposes. The integration of digital displays and programmable settings allows operators to customize temperature parameters based on specific application requirements and operational schedules.

Digital refrigerator temperature control systems offer significant advantages over traditional mechanical thermostats, including improved accuracy, reduced temperature fluctuations, and enhanced diagnostic capabilities. These systems can detect and respond to temperature deviations more quickly than mechanical alternatives, minimizing the risk of temperature excursions that could compromise stored products. The programmable nature of digital controllers also enables advanced features such as defrost scheduling, alarm functions, and remote monitoring capabilities.

Sensor Technology and Placement

Temperature sensors play a critical role in effective refrigerator temperature control by providing accurate feedback to the control system. Modern installations typically employ multiple sensors strategically placed throughout the refrigerated space to monitor temperature uniformity and detect potential hot spots or cold zones. The quality and calibration of these sensors directly impact the precision of temperature control and the overall reliability of the refrigeration system.

Proper sensor placement is essential for optimal refrigerator temperature control performance. Sensors should be positioned away from direct air flow, door openings, and heat sources to provide representative temperature readings. In commercial applications, multiple sensors may be networked together to provide comprehensive temperature monitoring across large refrigerated spaces, enabling zone-specific control and enhanced system optimization.

Calibration and Maintenance Procedures

Regular Calibration Requirements

Maintaining accurate refrigerator temperature control requires regular calibration of temperature sensors and control systems. Professional calibration should be performed at least annually, or more frequently in critical applications where temperature accuracy is paramount. Calibration procedures involve comparing sensor readings against certified reference thermometers and adjusting control parameters to ensure continued accuracy and reliability.

The calibration process for refrigerator temperature control systems typically involves multiple temperature points across the operating range to verify linearity and accuracy. Documentation of calibration results is essential for regulatory compliance and quality assurance programs. Many modern digital controllers include self-diagnostic features that can alert operators to potential calibration drift or sensor malfunctions before they impact temperature control performance.

Preventive Maintenance Strategies

Effective preventive maintenance is crucial for maintaining reliable refrigerator temperature control over the long term. Regular maintenance activities include cleaning temperature sensors, inspecting wiring connections, and verifying control system programming. These routine tasks help prevent system failures and ensure continued accuracy in temperature regulation. Scheduled maintenance should also include performance verification tests to confirm that the system maintains specified temperature ranges under various operating conditions.

Comprehensive maintenance programs for refrigerator temperature control systems should address both the control components and the mechanical refrigeration system. This includes cleaning condenser coils, checking refrigerant levels, and inspecting door seals to ensure optimal system efficiency. Poor mechanical performance can overwhelm even the most sophisticated temperature control system, making comprehensive maintenance essential for reliable operation.

Energy Efficiency and Optimization

Smart Control Algorithms

Advanced refrigerator temperature control systems incorporate intelligent algorithms that optimize compressor operation to minimize energy consumption while maintaining precise temperature control. These systems analyze historical temperature data, occupancy patterns, and ambient conditions to predict cooling requirements and adjust operation accordingly. Smart control strategies can reduce energy consumption by up to 30% compared to traditional on-off control methods.

Machine learning capabilities in modern refrigerator temperature control systems enable continuous optimization of cooling cycles based on actual usage patterns and environmental conditions. These systems can identify trends and adjust parameters automatically to maintain optimal performance while minimizing energy waste. The integration of variable-speed compressor control and intelligent defrost scheduling further enhances energy efficiency without compromising temperature stability.

Load Management Features

Professional refrigerator temperature control systems often include load management features that help balance energy consumption with temperature requirements. These features may include demand limiting, peak shaving, and scheduled operation modes that reduce energy consumption during high-cost periods while maintaining food safety standards. Advanced load management can significantly reduce operating costs in commercial applications where energy expenses represent a substantial portion of operational overhead.

The implementation of load management in refrigerator temperature control systems requires careful consideration of temperature recovery capabilities and food safety requirements. Systems must be designed to maintain critical temperatures even during reduced-power operation modes. This balance between energy efficiency and temperature control performance is achieved through sophisticated control algorithms that prioritize food safety while maximizing energy savings opportunities.

Troubleshooting Common Issues

Temperature Fluctuation Problems

Temperature fluctuations in refrigerator temperature control systems can result from various factors including sensor placement issues, control system malfunctions, or mechanical problems with the refrigeration equipment. Systematic troubleshooting approaches involve analyzing temperature logs, inspecting sensor locations, and verifying control system programming. Identifying the root cause of temperature instability is essential for implementing effective corrective measures.

Common causes of temperature fluctuation include dirty condenser coils, refrigerant leaks, and worn door seals that compromise system efficiency. Even advanced refrigerator temperature control systems cannot compensate for significant mechanical deficiencies in the refrigeration system. Regular maintenance and prompt attention to mechanical issues are essential for maintaining stable temperature control performance.

Alarm System Configuration

Proper alarm configuration is a critical component of effective refrigerator temperature control systems. Alarms should be set with appropriate deadbands to avoid nuisance alarms while ensuring prompt notification of significant temperature excursions. The alarm system should include both high and low temperature limits, with different setpoints for different zones or applications as required. Alarm delay settings should be configured to allow for normal temperature recovery after door openings or defrost cycles.

Modern refrigerator temperature control systems often include multiple alarm notification methods including audible alarms, visual indicators, and remote notifications via email or text message. The configuration of these alarm systems should consider staffing patterns, response procedures, and regulatory requirements. Comprehensive alarm documentation and response procedures are essential for maintaining effective temperature monitoring and ensuring rapid response to potential problems.

Installation and Setup Considerations

Environmental Factors

The installation environment significantly impacts the performance of refrigerator temperature control systems. Ambient temperature, humidity levels, and air circulation patterns can all affect system accuracy and reliability. Control system components should be installed in locations that provide stable environmental conditions and protection from extreme temperatures, moisture, and electromagnetic interference that could compromise performance.

Proper environmental consideration during installation includes evaluating heat sources, air flow patterns, and potential sources of temperature variation that could affect sensor readings. The control system enclosure should provide adequate protection while allowing necessary heat dissipation from electronic components. Environmental factors that are often overlooked during installation can significantly impact long-term reliability and accuracy of refrigerator temperature control systems.

Wiring and Communication Setup

Professional installation of refrigerator temperature control systems requires careful attention to wiring practices and communication setup. Sensor wiring should be properly shielded and routed away from power cables and sources of electromagnetic interference. Communication cables for networked systems must be installed according to manufacturer specifications to ensure reliable data transmission and system coordination.

The configuration of communication networks for refrigerator temperature control systems should consider data security, network reliability, and expansion capabilities. Modern systems often support multiple communication protocols and can integrate with building management systems or standalone monitoring platforms. Proper network setup is essential for maximizing the benefits of advanced monitoring and control features available in contemporary temperature control systems.

FAQ

What is the ideal temperature range for refrigerator temperature control systems

The ideal temperature range depends on the specific application, but generally, fresh food compartments should maintain temperatures between 35°F and 38°F (1.7°C to 3.3°C), while freezer sections should operate at 0°F (-18°C) or below. Commercial and laboratory applications may require more precise control within narrower temperature bands. Professional refrigerator temperature control systems can typically maintain accuracy within ±1°F (±0.5°C) of the setpoint when properly calibrated and maintained.

How often should refrigerator temperature control systems be calibrated

Calibration frequency depends on the criticality of the application and regulatory requirements. Generally, annual calibration is recommended for most commercial applications, while critical applications such as pharmaceutical storage may require semi-annual or quarterly calibration. Systems should also be calibrated after any major repairs, sensor replacement, or if temperature accuracy appears to be drifting. Regular calibration ensures continued accuracy and compliance with food safety and quality standards.

What are the signs that a refrigerator temperature control system needs repair

Common signs include frequent temperature alarms, inability to maintain setpoint temperatures, excessive energy consumption, and erratic compressor cycling. Visual indicators may include frost buildup, condensation issues, or display malfunctions. Temperature logs showing increasing variability or drift from setpoints also indicate potential problems. Any of these symptoms warrant professional evaluation to prevent food spoilage and ensure continued safe operation of the refrigeration system.

Can refrigerator temperature control systems be upgraded for better energy efficiency

Yes, many older systems can be upgraded with modern digital controllers that offer improved energy efficiency through smart control algorithms and variable-speed compressor control. Upgrades may include new temperature sensors, advanced control systems, and integration with building management systems for optimized operation. While the initial investment can be significant, energy savings and improved reliability often justify the upgrade costs, particularly in high-usage commercial applications where energy expenses are substantial.

Table of Contents

- Understanding Refrigeration Temperature Zones

- Digital Temperature Control Technologies

- Calibration and Maintenance Procedures

- Energy Efficiency and Optimization

- Troubleshooting Common Issues

- Installation and Setup Considerations

-

FAQ

- What is the ideal temperature range for refrigerator temperature control systems

- How often should refrigerator temperature control systems be calibrated

- What are the signs that a refrigerator temperature control system needs repair

- Can refrigerator temperature control systems be upgraded for better energy efficiency