Modern refrigerator temperature control systems have revolutionized how commercial and residential kitchens manage food preservation while optimizing energy consumption. Understanding the intricacies of refrigerator temperature control not only ensures food safety but also significantly reduces operational costs through intelligent energy management. Professional-grade refrigerator temperature control solutions offer precise monitoring capabilities that traditional thermostats simply cannot match, making them essential for businesses seeking to minimize waste and maximize efficiency.

The foundation of effective refrigerator temperature control lies in understanding the precise temperature requirements for different types of food products. Fresh produce, dairy items, and frozen goods each demand specific temperature ranges to maintain their nutritional value and prevent spoilage. Advanced refrigerator temperature control systems automatically adjust cooling cycles based on these requirements, ensuring optimal preservation conditions while preventing energy waste from over-cooling.

Digital Temperature Control Technology

Precision Monitoring Systems

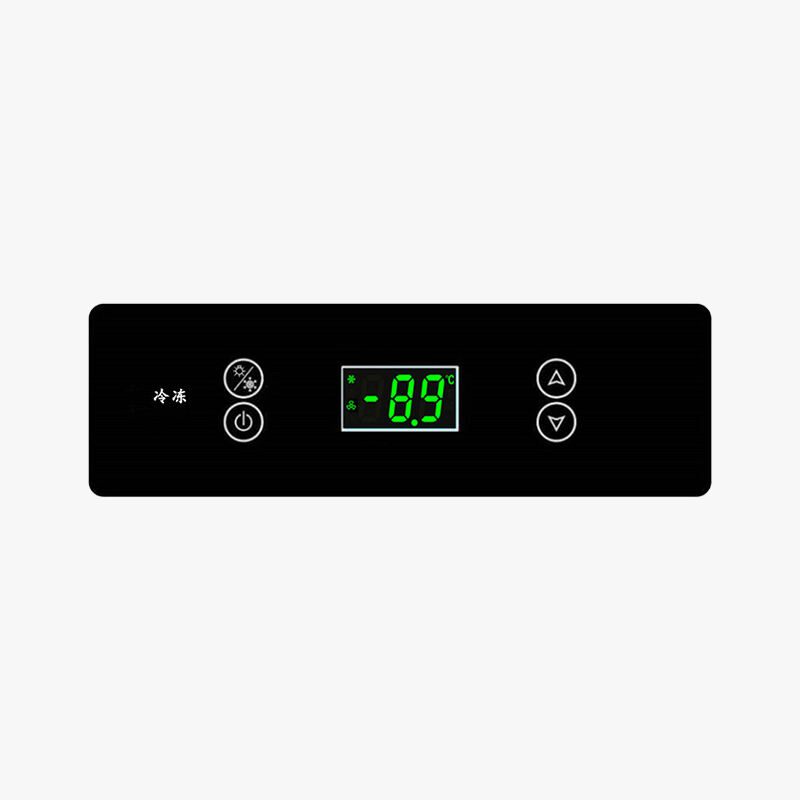

Digital refrigerator temperature control systems provide unprecedented accuracy in maintaining desired temperatures across different storage zones. These sophisticated controllers continuously monitor internal conditions and make micro-adjustments to compressor operation, ensuring temperature variations remain within acceptable ranges. The precision offered by modern refrigerator temperature control technology typically maintains temperatures within plus or minus one degree Fahrenheit, far exceeding the capabilities of mechanical thermostats.

Professional establishments benefit significantly from digital refrigerator temperature control systems that offer real-time data logging and alarm notifications. These features enable kitchen managers to track temperature trends over time, identify potential equipment issues before they result in product loss, and maintain compliance with food safety regulations. The integration of smartphone connectivity further enhances monitoring capabilities, allowing remote oversight of refrigerator temperature control systems from any location.

Smart Defrost Management

Intelligent refrigerator temperature control systems incorporate adaptive defrost cycles that optimize energy consumption while maintaining proper cooling performance. Traditional time-based defrost systems operate on fixed schedules regardless of actual frost accumulation, leading to unnecessary energy consumption. Advanced refrigerator temperature control technology analyzes evaporator conditions and initiates defrost cycles only when required, reducing energy usage by up to thirty percent compared to conventional systems.

The implementation of demand-based defrost management through sophisticated refrigerator temperature control systems ensures optimal compressor efficiency throughout operational cycles. This approach minimizes temperature fluctuations during defrost periods, maintaining consistent storage conditions while reducing overall energy consumption. Commercial kitchens utilizing these advanced systems report significant improvements in both energy efficiency and product quality retention.

Energy Efficiency Optimization Strategies

Load-Based Cooling Adjustments

Effective refrigerator temperature control involves dynamic adjustment of cooling capacity based on actual storage loads and ambient conditions. Modern controllers analyze factors such as door opening frequency, product loading patterns, and external temperature variations to optimize compressor operation. This intelligent approach to refrigerator temperature control reduces energy consumption during low-demand periods while ensuring adequate cooling capacity when fully loaded.

Commercial refrigeration systems equipped with advanced refrigerator temperature control technology can achieve energy savings of twenty to forty percent compared to basic mechanical controls. These savings result from optimized compressor cycling, reduced frost formation, and elimination of temperature overshooting. The cumulative effect of improved refrigerator temperature control translates to substantial reductions in monthly utility costs for restaurants, grocery stores, and food service establishments.

Ambient Temperature Compensation

Professional refrigerator temperature control systems incorporate ambient temperature sensors that automatically adjust cooling parameters based on external environmental conditions. During hot summer months, these systems proactively increase cooling capacity to maintain stable internal temperatures, while reducing energy consumption during cooler periods. This adaptive approach to refrigerator temperature control ensures consistent performance regardless of seasonal temperature variations.

The integration of weather data and predictive algorithms in modern refrigerator temperature control systems enables preemptive adjustments that maintain optimal storage conditions while minimizing energy waste. These systems can anticipate increased cooling demands during peak ambient temperature periods and adjust compressor operation accordingly. Such intelligent refrigerator temperature control capabilities are particularly valuable in facilities with variable climate control or those operating in regions with extreme temperature fluctuations.

Installation and Configuration Guidelines

Sensor Placement Optimization

Proper sensor placement is crucial for accurate refrigerator temperature control performance and optimal energy efficiency. Temperature sensors should be positioned in representative locations that reflect actual storage conditions, avoiding areas near cooling coils, door openings, or heat-generating equipment. Strategic sensor placement ensures that refrigerator temperature control systems receive accurate feedback for precise cooling adjustments.

Multiple sensor configurations enhance refrigerator temperature control accuracy in larger commercial units with distinct storage zones. Each zone requires independent monitoring to accommodate different product types and their specific temperature requirements. Professional installation of refrigerator temperature control systems includes calibration procedures that verify sensor accuracy and establish baseline operating parameters for optimal performance.

Programming and Calibration Procedures

Initial configuration of refrigerator temperature control systems requires careful attention to setpoint parameters, differential settings, and alarm thresholds. These parameters determine how aggressively the system responds to temperature deviations and influence overall energy consumption patterns. Proper calibration of refrigerator temperature control systems ensures responsive cooling while preventing excessive cycling that wastes energy.

Advanced refrigerator temperature control systems offer programmable scheduling features that allow customized operation based on facility usage patterns. These capabilities enable reduced cooling during off-hours, weekend setbacks, and seasonal adjustments that significantly impact energy consumption. Regular calibration maintenance ensures continued accuracy of refrigerator temperature control systems and prevents drift that could compromise both food safety and energy efficiency.

Maintenance and Troubleshooting

Preventive Maintenance Protocols

Regular maintenance of refrigerator temperature control components ensures reliable operation and sustained energy efficiency throughout the system lifespan. Cleaning temperature sensors, checking electrical connections, and verifying calibration accuracy are essential maintenance tasks that prevent performance degradation. Systematic maintenance of refrigerator temperature control systems reduces the likelihood of unexpected failures and extends equipment longevity.

Documentation of maintenance activities and performance trends provides valuable insights into refrigerator temperature control system health and optimization opportunities. Tracking energy consumption patterns, temperature stability metrics, and alarm frequency helps identify potential issues before they impact operations. Proactive maintenance approaches to refrigerator temperature control systems typically result in lower total cost of ownership and improved reliability.

Common Performance Issues

Temperature oscillations often indicate improper refrigerator temperature control settings or sensor placement problems that require professional attention. Excessive cycling, prolonged cooling periods, and inconsistent temperature readings are symptoms of refrigerator temperature control issues that impact both food safety and energy consumption. Early identification and correction of these problems prevent more serious equipment damage and operational disruptions.

Modern refrigerator temperature control systems provide diagnostic capabilities that simplify troubleshooting and reduce service time requirements. Built-in error codes, historical data logging, and remote monitoring features enable technicians to quickly identify root causes of performance problems. These advanced diagnostic features make refrigerator temperature control systems more reliable and easier to maintain than traditional mechanical controls.

Cost-Benefit Analysis

Energy Savings Calculations

Investment in advanced refrigerator temperature control systems typically generates positive returns through reduced energy consumption and improved operational efficiency. Energy savings of twenty-five to forty percent are commonly achieved when upgrading from mechanical thermostats to digital refrigerator temperature control systems. These savings compound over time, with most commercial installations recovering upgrade costs within eighteen to twenty-four months.

Calculating energy savings from improved refrigerator temperature control requires consideration of baseline consumption, local utility rates, and operational patterns. Professional energy audits can quantify potential savings and establish realistic payback periods for refrigerator temperature control upgrades. The combination of reduced energy costs and improved food preservation makes advanced refrigerator temperature control systems attractive investments for commercial food service operations.

Operational Benefits Beyond Energy Savings

Enhanced food safety compliance through precise refrigerator temperature control reduces liability risks and potential losses from temperature-related spoilage. Consistent temperature maintenance extends product shelf life, reducing waste and inventory replacement costs. These operational benefits often exceed the direct energy savings achieved through improved refrigerator temperature control systems.

Remote monitoring capabilities of modern refrigerator temperature control systems reduce labor requirements for manual temperature checking and documentation. Automated data logging ensures compliance with regulatory requirements while freeing staff for more productive activities. The operational efficiency gains from advanced refrigerator temperature control technology contribute significantly to overall profitability improvements in commercial food service environments.

FAQ

How often should refrigerator temperature control systems be calibrated

Professional refrigerator temperature control systems should undergo calibration verification at least twice annually, with more frequent checking recommended for critical applications such as pharmaceutical storage or high-volume food service operations. Regular calibration ensures accuracy within acceptable tolerances and maintains compliance with food safety regulations that depend on precise temperature monitoring.

What temperature differential settings provide optimal energy efficiency

Most refrigerator temperature control systems achieve optimal energy efficiency with differential settings between two and four degrees Fahrenheit, balancing responsive cooling with reduced compressor cycling. Smaller differentials provide tighter temperature control but may increase energy consumption through frequent cycling, while larger differentials reduce cycling but allow greater temperature variations that could compromise food quality.

Can existing mechanical thermostats be upgraded to digital refrigerator temperature control

Most commercial refrigeration systems can accommodate digital refrigerator temperature control upgrades with minimal modifications to existing equipment. The upgrade process typically involves replacing the mechanical thermostat with a digital controller and installing appropriate temperature sensors, while utilizing existing wiring and control circuits. Professional installation ensures proper integration and optimal performance of upgraded refrigerator temperature control systems.

What backup systems are recommended for critical refrigerator temperature control applications

Critical applications require redundant refrigerator temperature control systems with independent sensors, backup power supplies, and alarm notification systems to ensure continuous operation during equipment failures or power outages. Battery backup systems maintain monitoring capabilities during brief power interruptions, while generator backup ensures continued refrigeration during extended outages that could compromise product safety and quality.

Table of Contents

- Digital Temperature Control Technology

- Energy Efficiency Optimization Strategies

- Installation and Configuration Guidelines

- Maintenance and Troubleshooting

- Cost-Benefit Analysis

-

FAQ

- How often should refrigerator temperature control systems be calibrated

- What temperature differential settings provide optimal energy efficiency

- Can existing mechanical thermostats be upgraded to digital refrigerator temperature control

- What backup systems are recommended for critical refrigerator temperature control applications