Modern refrigeration systems rely heavily on precise temperature management to maintain food safety and energy efficiency. When your refrigerator temperature control malfunctions, it can lead to spoiled food, increased energy costs, and potential health risks. Understanding the common issues that affect refrigerator temperature control systems helps homeowners and technicians identify problems early and implement effective solutions. These temperature control problems can range from simple calibration issues to complex electronic component failures that require professional intervention.

Understanding Refrigerator Temperature Control Systems

Basic Components and Operation

Refrigerator temperature control systems consist of several interconnected components that work together to maintain optimal cooling conditions. The main thermostat serves as the central control unit, monitoring internal temperatures and signaling the compressor to start or stop cooling cycles. Temperature sensors positioned throughout the refrigerator compartments provide continuous feedback to ensure accurate temperature readings. The control board processes this information and coordinates the operation of various components including fans, defrost heaters, and damper controls.

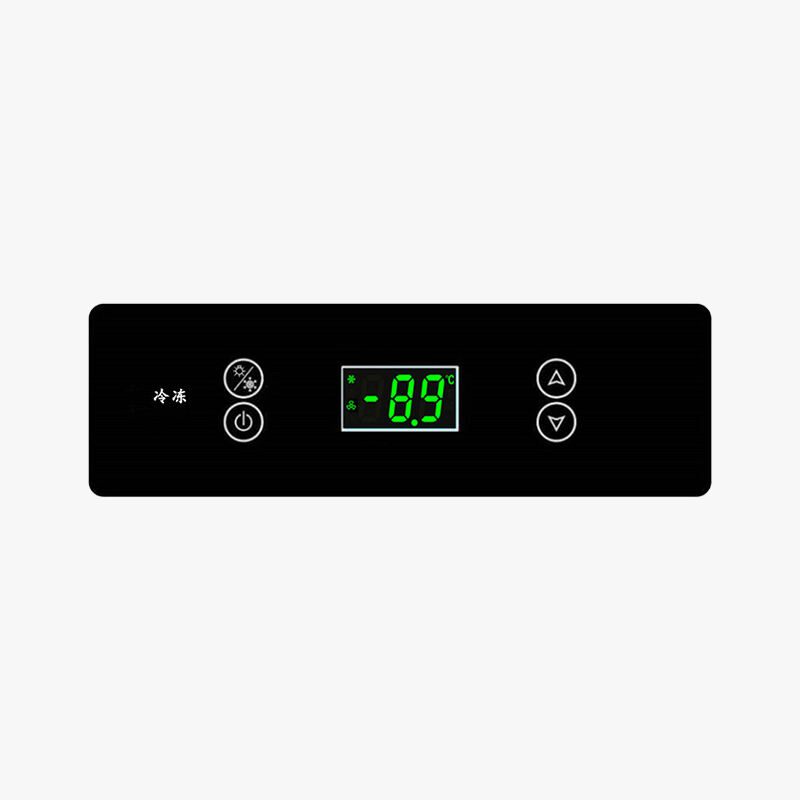

Digital temperature controllers have become increasingly popular in modern refrigeration systems due to their precision and programmable features. These advanced controllers offer superior accuracy compared to traditional mechanical thermostats, allowing for temperature variations within one degree Fahrenheit. The electronic sensors used in these systems respond quickly to temperature changes, enabling more efficient cooling cycles and better energy management.

Temperature Zones and Optimal Settings

Different sections of a refrigerator require specific temperature ranges to ensure proper food preservation. The main refrigerator compartment should maintain temperatures between 37°F and 40°F, while freezer sections need to stay at 0°F or below. Many modern units feature multi-zone cooling systems with independent temperature controls for different compartments, allowing users to customize settings based on stored items.

Proper refrigerator temperature control also involves understanding how air circulation affects cooling efficiency. Cold air naturally sinks while warm air rises, creating temperature gradients within the refrigerator. Strategic placement of temperature sensors helps controllers compensate for these variations and maintain consistent cooling throughout all compartments.

Common Temperature Control Malfunctions

Thermostat Calibration Issues

One of the most frequent problems affecting refrigerator performance is improper thermostat calibration. Over time, mechanical thermostats can drift from their original settings due to wear, vibration, or temperature fluctuations. This results in temperatures that are consistently too warm or too cold, regardless of the dial setting. Digital controllers may also experience calibration problems due to sensor drift or software glitches.

Calibration problems often manifest as inconsistent cooling performance, with the refrigerator struggling to maintain set temperatures. Users may notice that adjusting the temperature control dial has little effect on actual internal temperatures. In some cases, the cooling system may cycle too frequently or run continuously, indicating that the controller is receiving incorrect temperature feedback.

Sensor Failures and Wiring Problems

Temperature sensors are critical components that can fail due to moisture exposure, physical damage, or electrical issues. When sensors malfunction, they may provide incorrect readings to the control system, causing erratic cooling behavior. Common sensor problems include open circuits, short circuits, and resistance drift that affects measurement accuracy.

Wiring connections between sensors and control boards can also deteriorate over time, especially in the humid environment inside refrigerators. Corroded connections, loose terminals, and damaged wire insulation can interrupt signal transmission and cause intermittent control problems. These issues often require careful electrical testing to identify and resolve properly.

Diagnostic Procedures and Testing Methods

Visual Inspection and Basic Testing

The diagnostic process begins with a thorough visual inspection of the temperature control system components. Check for obvious signs of damage such as cracked housings, corroded terminals, or loose connections. Examine the control panel for error codes or warning indicators that might provide clues about specific malfunctions. Many modern units include diagnostic modes that can help identify system problems.

Basic temperature testing involves using accurate thermometers to verify actual refrigerator temperatures against control settings. Place calibrated thermometers in multiple locations throughout the refrigerator and freezer compartments, allowing sufficient time for temperature stabilization. Compare these readings with the control panel display to identify discrepancies that indicate calibration problems.

Advanced Electrical Testing

Electrical testing requires specialized equipment and knowledge of refrigerator control circuits. Use a multimeter to check sensor resistance values, verifying that they fall within manufacturer specifications for the current temperature. Test continuity in wiring harnesses and measure voltage levels at various control points to identify electrical faults.

Advanced diagnostic procedures may involve accessing service menus or using manufacturer-specific testing protocols. Some systems require specialized diagnostic tools that can communicate with the control board to retrieve error logs and perform automated tests. Professional technicians often use these tools to quickly identify complex control system problems.

Repair Solutions and Component Replacement

Thermostat and Controller Replacement

When thermostat calibration cannot be corrected through adjustment, replacement becomes necessary. Mechanical thermostats are typically straightforward to replace, requiring only basic hand tools and careful attention to wire connections. Digital controllers may require more complex installation procedures, including programming and calibration steps.

Selecting the correct replacement refrigerator temperature control component is crucial for proper system operation. Match part numbers exactly and verify compatibility with the existing refrigerator model. Modern digital controllers often offer enhanced features such as programmable temperature profiles, alarm functions, and remote monitoring capabilities.

Sensor and Wiring Repairs

Temperature sensor replacement typically involves accessing internal refrigerator components, which may require removing shelves, panels, or other parts. Handle sensors carefully to avoid damage during installation, and ensure proper routing of sensor cables to prevent interference with moving parts. Use appropriate sealants or grommets to protect connections from moisture.

Wiring repairs should follow proper electrical safety procedures and use materials rated for refrigeration applications. Replace damaged wire sections with appropriate gauge conductors and use moisture-resistant connectors where necessary. Secure all wiring to prevent movement that could cause wear or damage over time.

Preventive Maintenance and Best Practices

Regular Calibration Checks

Implementing a regular maintenance schedule helps prevent temperature control problems before they affect refrigerator performance. Check temperature accuracy monthly using calibrated thermometers, comparing actual temperatures with control settings. Document any drift patterns that might indicate developing calibration issues requiring attention.

Clean control components periodically to remove dust, grease, and moisture that can affect operation. Use appropriate cleaning methods for different component types, avoiding harsh chemicals that might damage sensitive electronic parts. Inspect wiring connections for signs of corrosion or looseness that could lead to future problems.

Environmental Considerations

Proper refrigerator placement and environmental conditions significantly impact temperature control system performance. Ensure adequate ventilation around the unit and maintain stable ambient temperatures when possible. Avoid locations near heat sources or areas with extreme temperature fluctuations that can stress control components.

Monitor loading patterns and door usage habits that affect internal temperatures. Overloading compartments can restrict air circulation and create hot spots that challenge the control system. Frequent door opening allows warm air infiltration that forces the system to work harder to maintain set temperatures.

Troubleshooting Tips for Homeowners

Simple Problem Resolution

Many refrigerator temperature control issues can be resolved through basic troubleshooting steps that homeowners can perform safely. Start by verifying that the unit is receiving power and that control settings have not been accidentally changed. Check for blocked air vents or dirty condenser coils that might affect cooling efficiency.

Reset the control system by unplugging the refrigerator for several minutes, then restoring power and allowing the system to stabilize. This simple procedure can resolve temporary glitches in electronic controls and restore normal operation. Monitor temperatures for several hours after reset to ensure stable performance.

When to Call Professional Service

Recognize the limitations of DIY repairs and know when professional service is required. Complex electrical problems, refrigerant system issues, and warranty concerns typically require qualified technician intervention. Attempting advanced repairs without proper training and tools can cause additional damage and safety hazards.

Document problem symptoms and any troubleshooting steps already attempted before contacting service technicians. This information helps professionals diagnose issues more efficiently and may reduce service call costs. Keep maintenance records and warranty documentation readily available for reference during service visits.

FAQ

Why does my refrigerator temperature fluctuate even when the thermostat setting remains unchanged

Temperature fluctuations typically occur due to several factors including defective temperature sensors, worn thermostat contacts, or inadequate air circulation. Environmental changes such as frequent door opening, overloading, or placement near heat sources can also cause temperature variations. Check for blocked vents, clean condenser coils, and verify that the thermostat calibration is accurate using an independent thermometer.

How can I tell if my refrigerator temperature control sensor needs replacement

Signs of sensor failure include erratic temperature readings, failure to respond to thermostat adjustments, continuous running or cycling, and inconsistent cooling performance. You can test sensor accuracy by comparing actual internal temperatures with control display readings using calibrated thermometers. If discrepancies persist after thermostat calibration attempts, sensor replacement is likely necessary.

What temperature settings provide optimal food preservation and energy efficiency

Set refrigerator compartments between 37°F and 40°F, with 38°F being ideal for most food items. Freezer sections should maintain 0°F to -5°F for optimal frozen food quality. These settings balance food safety requirements with energy consumption, preventing excessive cooling that wastes electricity while ensuring adequate preservation temperatures.

Can I upgrade my mechanical thermostat to a digital temperature controller

Upgrading to digital controls is often possible but requires compatibility verification with your refrigerator model and electrical system. Digital controllers offer improved accuracy, programmable features, and better energy management compared to mechanical thermostats. Consult manufacturer specifications or professional technicians to determine suitable upgrade options and installation requirements for your specific unit.

Table of Contents

- Understanding Refrigerator Temperature Control Systems

- Common Temperature Control Malfunctions

- Diagnostic Procedures and Testing Methods

- Repair Solutions and Component Replacement

- Preventive Maintenance and Best Practices

- Troubleshooting Tips for Homeowners

-

FAQ

- Why does my refrigerator temperature fluctuate even when the thermostat setting remains unchanged

- How can I tell if my refrigerator temperature control sensor needs replacement

- What temperature settings provide optimal food preservation and energy efficiency

- Can I upgrade my mechanical thermostat to a digital temperature controller