Understanding Modern Temperature Control in Cooling Systems

The evolution of refrigeration technology has brought us to an era where precise temperature control is not just a luxury but a necessity. At the heart of this revolution lies the digital thermometer, a sophisticated device that has transformed how we monitor and manage cooling systems. Whether in commercial refrigeration units or residential applications, the implementation of digital temperature monitoring has become increasingly critical for maintaining optimal performance and energy efficiency.

Modern refrigeration systems depend heavily on accurate temperature readings to maintain consistent cooling levels. The integration of digital thermometer technology has made it possible to achieve unprecedented precision in temperature control, leading to better food preservation, reduced energy consumption, and improved system longevity. This comprehensive guide will explore the various aspects of digital temperature monitoring in refrigeration systems and help you understand how to maximize their potential.

Core Components of Digital Temperature Monitoring

Sensor Technology and Accuracy

The foundation of any digital thermometer system lies in its sensing capabilities. Modern temperature sensors utilize advanced thermistor technology, offering readings accurate to within 0.1 degrees Celsius. These sensors can rapidly detect temperature changes, allowing for immediate system response and adjustment. The precision of digital temperature monitoring helps maintain optimal conditions while preventing unnecessary system cycling.

Digital sensors also benefit from built-in calibration features and error-correction algorithms, ensuring consistent accuracy over time. This level of precision is particularly crucial in commercial refrigeration applications where even minor temperature fluctuations can impact product quality and safety.

Display and Interface Features

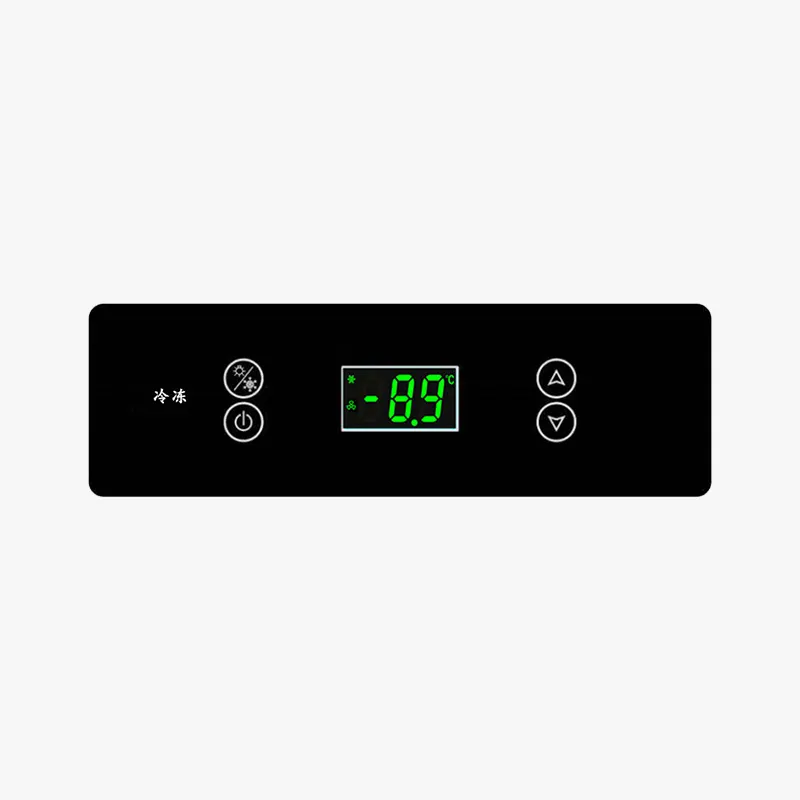

Contemporary digital thermometer systems come equipped with clear LCD displays that provide real-time temperature readings and system status information. The interface typically includes programmable alarm settings, temperature history logging, and customizable display options. These features enable users to monitor system performance effectively and respond promptly to any irregularities.

Advanced models often incorporate touchscreen technology and wireless connectivity, allowing for remote monitoring and control through smartphone applications or building management systems. This connectivity has revolutionized how facility managers and homeowners interact with their refrigeration systems.

Integration with Refrigeration Control Systems

Communication Protocols

Modern digital thermometer systems utilize various communication protocols to interface with refrigeration controls. Common standards include Modbus, BACnet, and proprietary protocols developed by manufacturers. These protocols enable seamless integration with existing building automation systems and allow for sophisticated control strategies.

The ability to network multiple temperature sensors and control points creates a comprehensive monitoring system that can optimize performance across entire facilities. This networked approach is particularly valuable in large commercial installations where coordinated control is essential.

Smart Control Algorithms

The integration of digital thermometer technology with smart control algorithms has enabled advanced features such as predictive maintenance and adaptive cooling strategies. These systems can learn from historical temperature patterns and adjust operation parameters automatically to maintain optimal conditions while minimizing energy consumption.

Machine learning algorithms can identify potential system issues before they become critical, allowing for proactive maintenance and reducing downtime. This predictive capability has become increasingly important in commercial and industrial refrigeration applications.

Energy Efficiency and Cost Savings

Optimization Strategies

Digital temperature monitoring systems contribute significantly to energy efficiency through precise control and smart scheduling. By maintaining exact temperature setpoints and reducing system cycling, these systems can achieve substantial energy savings compared to traditional analog controls.

Advanced digital thermometer installations can implement sophisticated strategies such as floating setpoint control and demand-based operation, further improving efficiency. These features allow systems to adjust automatically to changing conditions while maintaining optimal performance.

Return on Investment Analysis

The implementation of digital temperature monitoring systems typically shows a compelling return on investment through reduced energy consumption and maintenance costs. Studies have shown that properly configured digital controls can reduce refrigeration energy usage by 15-30% compared to conventional systems.

Additional savings come from improved product preservation, reduced waste, and extended equipment life due to more stable operation. These benefits make the transition to digital temperature control an attractive investment for most applications.

Installation and Maintenance Considerations

Proper Sensor Placement

The effectiveness of a digital thermometer system depends heavily on proper sensor placement. Sensors should be located in areas that provide representative temperature readings while avoiding direct airflow or heat sources that could affect accuracy. Multiple sensors may be required for large spaces or systems with varying temperature zones.

Regular calibration and verification of sensor accuracy ensure reliable system performance over time. Most modern digital systems include self-diagnostic features that can alert users to sensor drift or potential failures.

System Updates and Calibration

Digital temperature monitoring systems require periodic software updates and calibration to maintain optimal performance. Manufacturers typically provide regular firmware updates that add features and improve system reliability. Establishing a regular maintenance schedule helps ensure continued accurate operation and maximum benefit from the technology.

Professional calibration services can verify and adjust sensor accuracy to maintain compliance with industry standards and regulatory requirements. This is particularly important in applications where precise temperature control is critical for product safety or quality.

Frequently Asked Questions

How accurate are digital thermometer systems compared to analog alternatives?

Digital thermometer systems typically offer accuracy within ±0.1°C to ±0.5°C, significantly better than traditional analog systems which may vary by ±2°C or more. This improved accuracy leads to better temperature control and more efficient system operation.

What are the maintenance requirements for digital temperature monitoring systems?

Regular maintenance includes sensor calibration checks every 6-12 months, cleaning of sensor components, software updates, and battery replacement for wireless units. Most systems also benefit from annual professional inspection to ensure optimal performance.

Can digital thermometer systems be integrated with existing refrigeration equipment?

Yes, most modern digital thermometer systems are designed to work with existing refrigeration equipment through various communication protocols and adapters. Professional installation ensures proper integration and optimal system performance.